Welding Works

We perform a full range of welding works at hazardous industrial facilities. Work is carried out by trained and certified personnel using modern equipment and materials according to technologies certified in the NAKS (National Welding Control Agency) welding production system, which confirms a high level of quality and industrial safety. We ensure the reliability and quality of welded joints in the manufacture, installation, repair, and reconstruction of technical devices at hazardous industrial facilities.

Полный комплекс сварочных работ на опасных производственных объектах. Работы проводятся обученным и аттестованным персоналом с применением современного оборудования и материалов по технологиям, аттестованным в системе сварочного производства НАКС.

Needs We Address

.webp)

Ensuring the safe operation of equipment and metal structures at hazardous industrial facilities

Installation and repair of building structures, pipelines, and equipment

Creation of protective structures for equipment, including enclosures against external threats

Guaranteeing compliance of welding works with industrial safety norms for hazardous industrial facilities

Stages of Service Provision

01

Preparation and Design

analysis of the object, selection of welding technology, development of design solutions

01

Preparation and Design analysis of the object, selection of welding technology, development of design solutions

02

Certification and Approval

confirmation of the right to perform work under the NAKS system and compliance with industrial safety requirements

02

Certification and Approval confirmation of the right to perform work under the NAKS system and compliance with industrial safety requirements

03

Performance of Welding Works

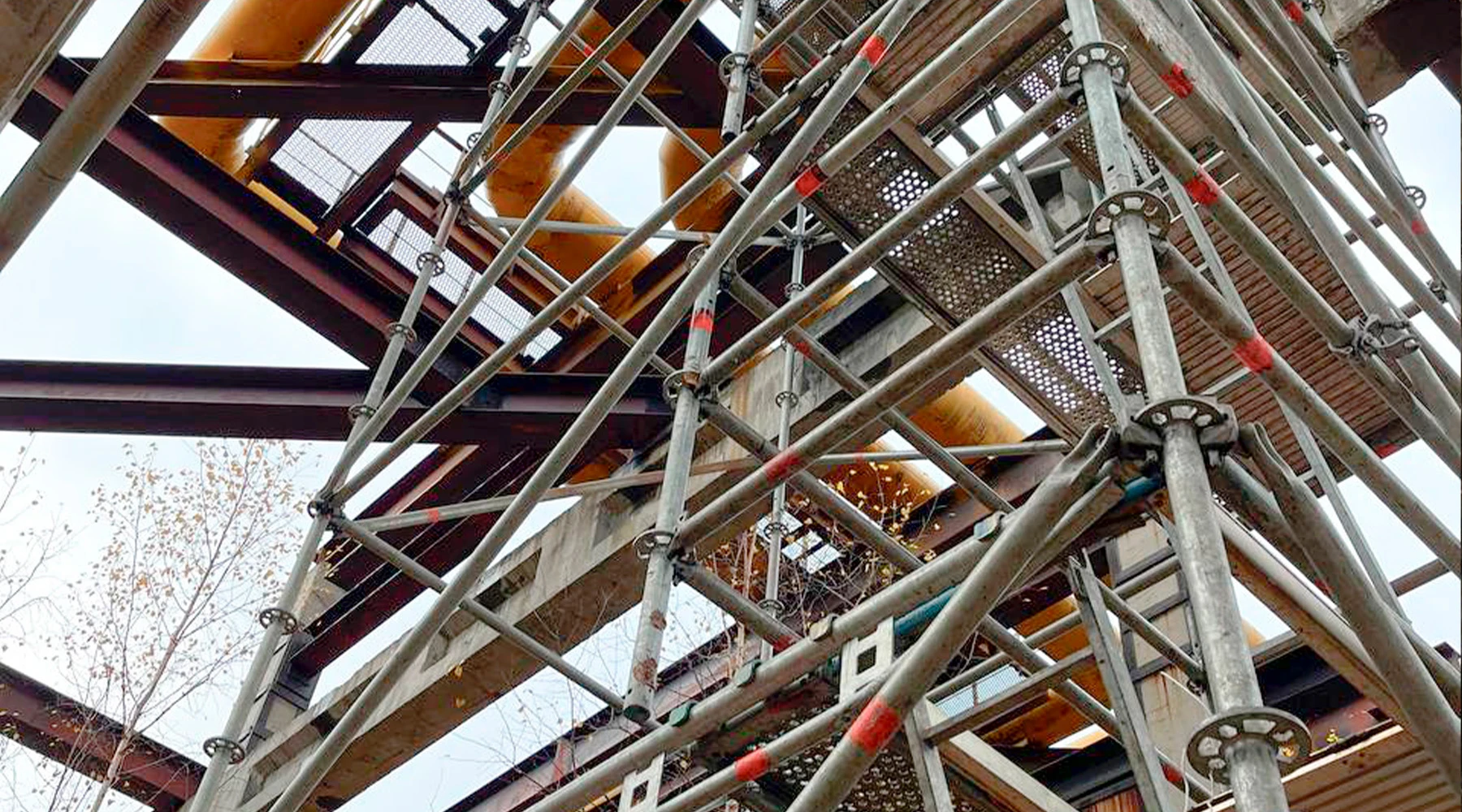

installation and welding of metal structures, pipelines, and equipment on site

03

Performance of Welding Works installation and welding of metal structures, pipelines, and equipment on site

04

Quality Control and Handover

testing of welded joints, preparation of as-built documentation, handover of the object to the customer

04

Quality Control and Handover testing of welded joints, preparation of as-built documentation, handover of the object to the customer

.webp)

01 | Preparation and Design

At this stage, our engineers assess the specifics of the object, select optimal equipment and materials, evaluate the required personnel qualifications, ensure the certification of the welding technology, and develop a work plan. This guarantees efficiency and risk minimization.

02 | Certification and Approval

All welding technologies undergo mandatory certification in NAKS. Currently, an assessment of the enterprise's readiness to perform welding work on metal building structures, boiler equipment pipelines, as well as pipelines for the chemical and petrochemical industry, manufactured from carbon and low-alloy steels, has been conducted with a positive conclusion for POLATI company.

03 | Performance of Welding Works

Work is performed strictly in accordance with industrial safety standards.

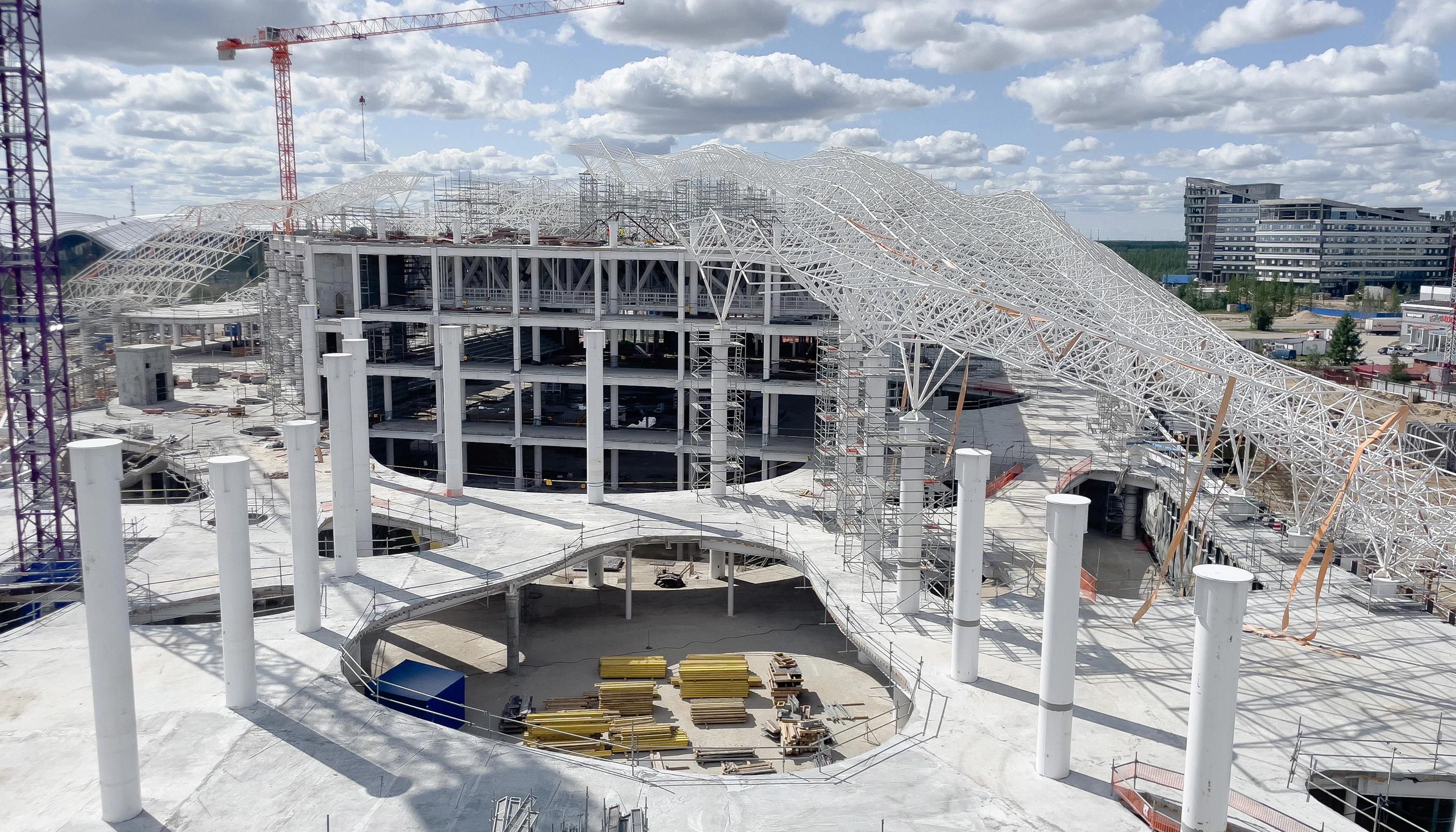

A number of projects have already been implemented, for example, in Novomoskovsk (Tula Region), where the company installed protective guards for technological equipment of the plant, affecting its safe operation. Also at this site, a set of works on the modernization of metal structures for technological equipment service platforms was completed.

.webp)

04 | Quality Control and Handover

All connections undergo quality control, including destructive and non-destructive testing methods.

Upon completion of work, the customer receives a full set of as-built documentation confirming compliance with regulatory requirements.

/Хайдельберг_2.webp)

.webp)

.webp)

.webp)