Industrial thermal insulation combines insulating materials, installation accessories, and protective cladding to form a continuous thermal barrier around the insulated asset.

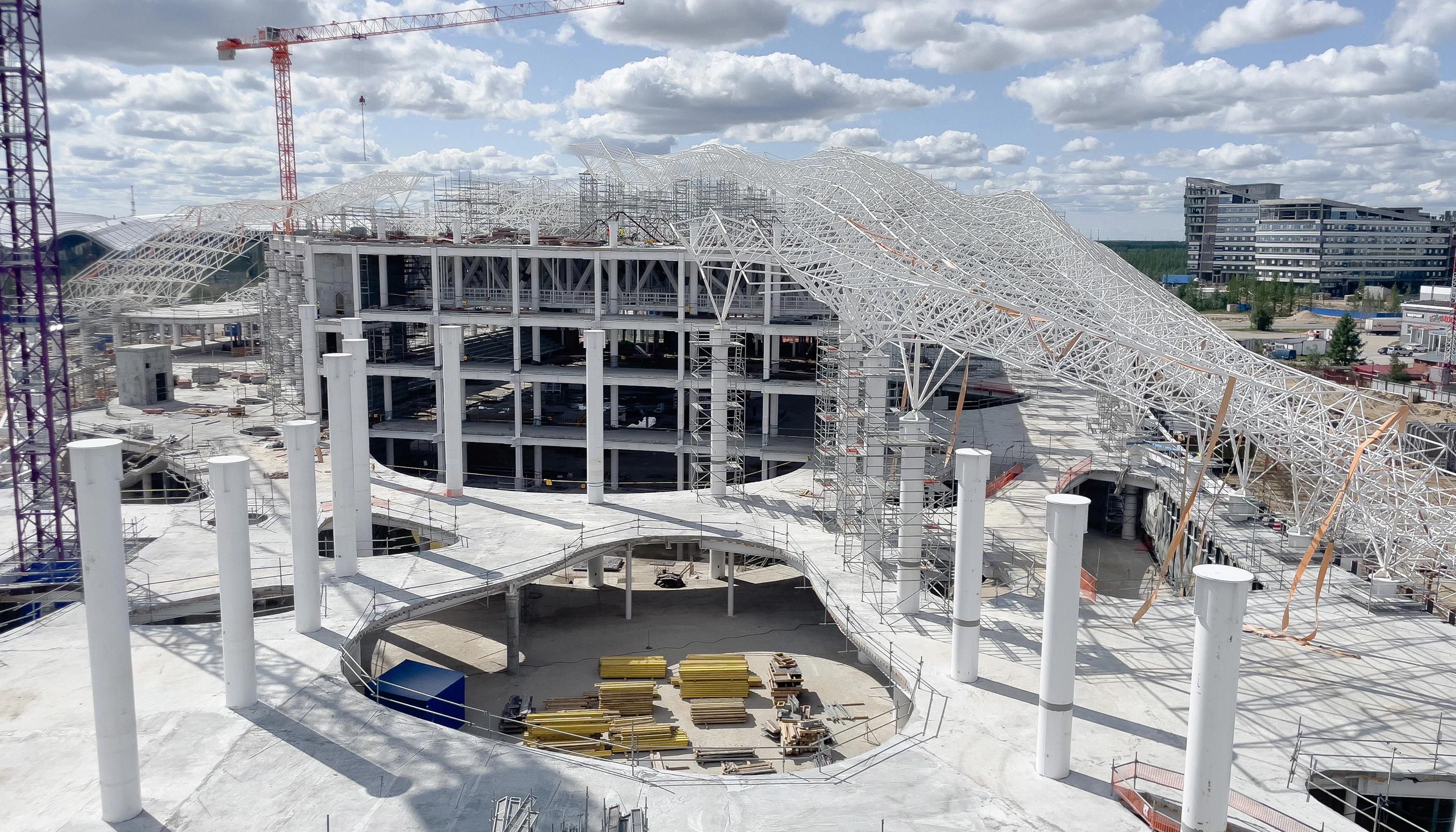

Insulation and Protection of Structures

POLATI Company provides a range of coating and structural protection services

Комплекс услуг по монтажу, демонтажу, ремонту тепловой изоляции и защите покрытий и конструкций

01 | Thermal Insulation

Services

POLATI specialists work with any type of thermal insulation material:

- mineral wool and quilted canvas;

- foam glass;

- foam rubber;

- aerogels;

multi-layer insulation made from various types of insulating materials.

01

Minimizing heat loss and limiting surface temperatures02

Preventing condensation and ice formation03

Protection against freezing and overheating04

Noise insulation05

Fire protection06

Reducing resource consumption for heating or cooling01

Minimizing heat loss and limiting surface temperatures02

Preventing condensation and ice formation03

Protection against freezing and overheating04

Noise insulation05

Fire protection06

Reducing resource consumption for heating or cooling02 | Sandblasting operations

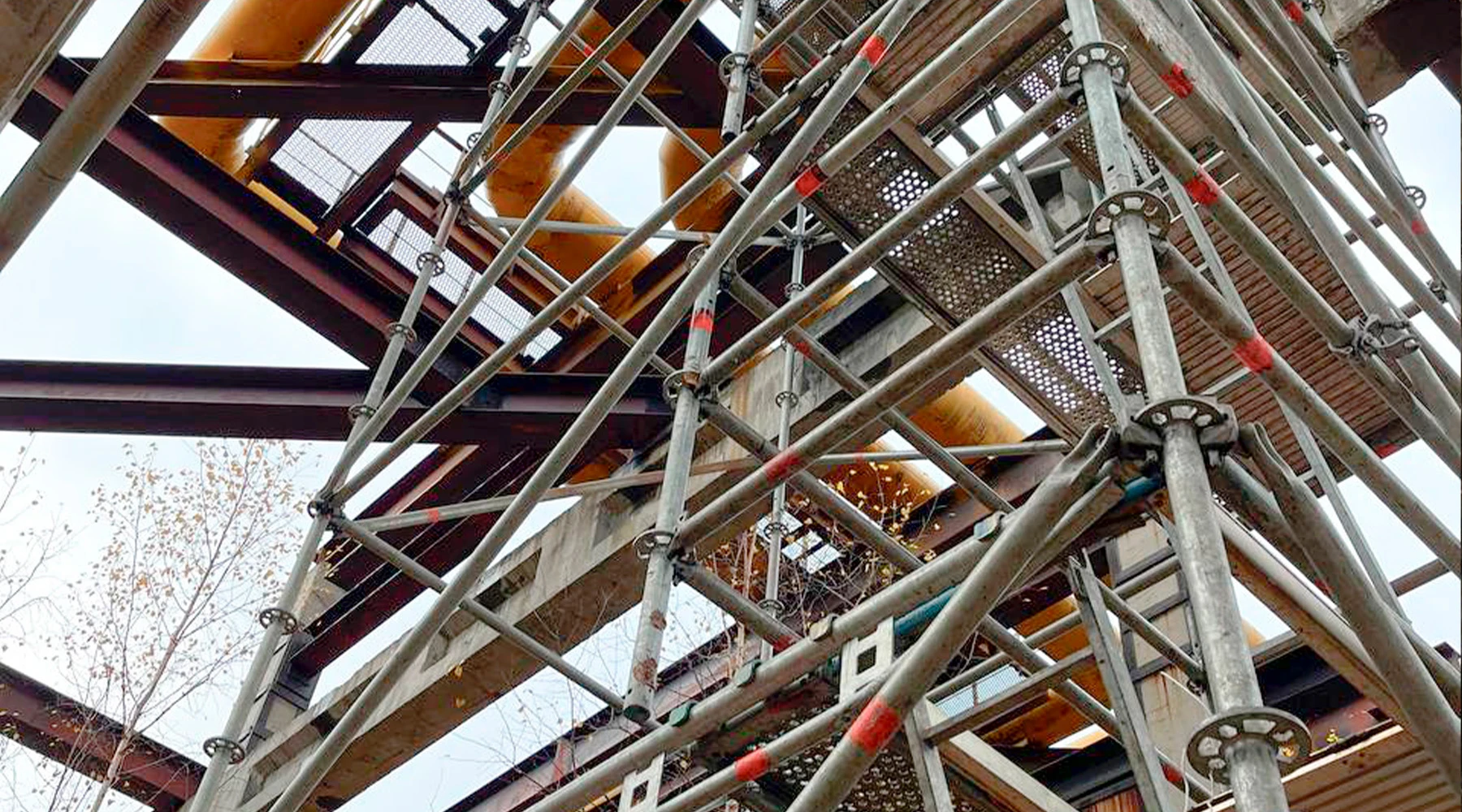

POLATI performs sandblasting work at various large industrial facilities, including using rope access.

Sandblasting is one of the most cost-effective and yet high-quality methods of cleaning various contaminants, degreasing, and preparing metal surfaces for the application of anti-corrosion protection, fire protection, and painting.

Advantages of working with us

Sandblasting is considered the cheapest method of metalworking compared to the use of chemicals and manual work

Sandblasting is 7-10 times faster than other blasting methods

Sandblasting is suitable even for surfaces with hard-to-reach parts, curves and corners

Only natural materials are used for sandblasting

The durability of the construction is directly dependent on the adhesion level

03 | Fire protection

POLATI company provides fire protection services for metal structures of industrial and civil facilities

POLATI company provides fire protection services for metal structures of industrial and civil facilities

metal heating temperature

A decrease in mechanical strength leads to the collapse of load-bearing metal structures at industrial and civil engineering facilities. To avoid such situations, POLATI provides a fire protection service for metal structures.

A flame retardant for metal protects structures from overheating, which makes it possible to multiply the fire resistance limit. The application of fire protection is required for both industrial and civilian facilities, but for industrial facilities it is necessary to choose more resistant coatings that withstand the effects of aggressive environments.

04 | Anti-corrosion protection and painting

In the absence of an anti-corrosion coating, the steel is exposed to corrosion, which can lead to structural failure. The construction of new and repair of current enterprises and structures can be carried out only if anti-corrosion protection is applied.

POLATI Company provides anti-corrosion protection of metal, concrete and reinforced concrete structures at the largest industrial facilities in Russia, such as Arctic LNG 2 and Amur Gas Processing Plant.

The service is provided in accordance with the following steps:

Stages of work

1. Inspection of the work area

01Inspection of the work area

2. Agreement on Cooperation Terms

02Agreement on Cooperation Terms

3. Contract Signing

03Contract Signing

4. Work Execution

04Work Execution

5. Quality Check of Completed Work

05Quality Check of Completed Work

/Хайдельберг_2.webp)

.webp)

.webp)

.webp)