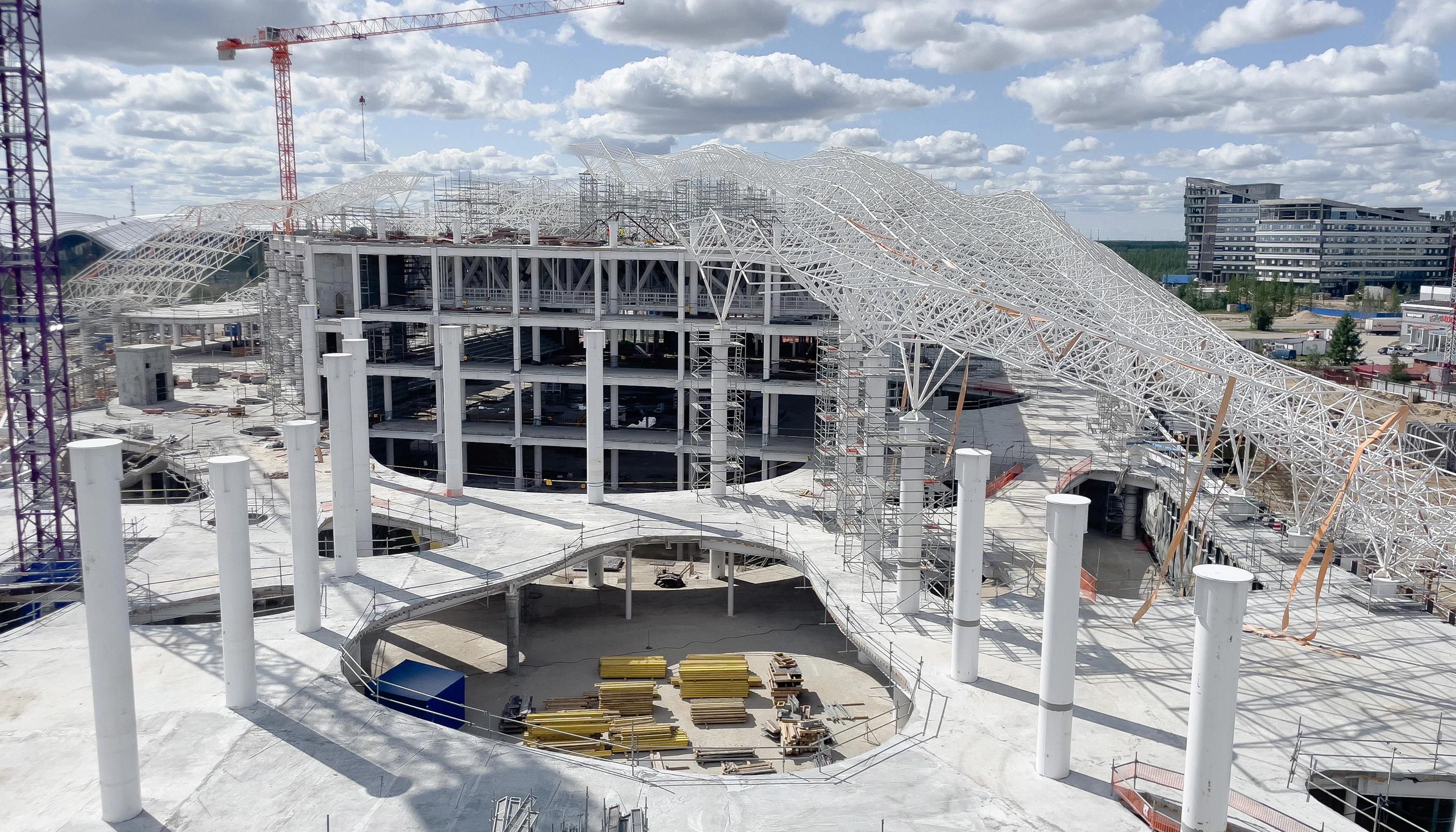

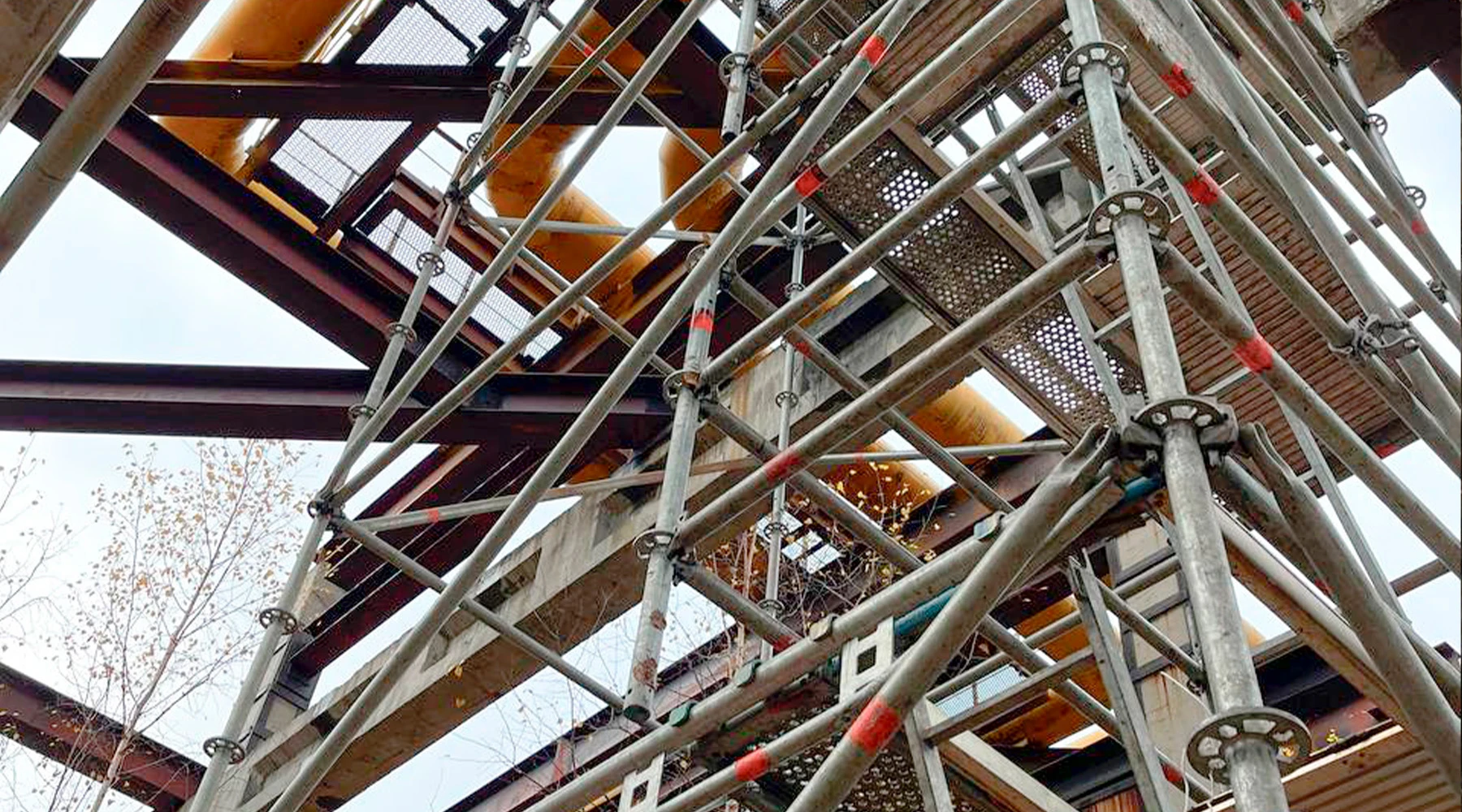

Building Scaffolding

POLATI provides a full range of services for the sale, rental, and installation of modern scaffolding systems anywhere in the world. Our main business area is large construction and industrial facilities.

How we work

Site audit and project development with the customer

Drawing up a detailed project estimate

Preparation of blueprints

Calculation and presentation of work schedule dividing by mobilization of people, transport, materials and scaffolding

Preparation of the Work Production Project and all necessary documents

Drawing up a client-friendly form for receiving applications and delivering completed work and reports

Types of scaffolding

Wedge scaffolding

They are an important element of construction technologies, providing convenient and safe access to work sites. Their main structure consists of tubular elements, which gives them lightness and strength.

Key elements of wedge forests:

1. Vertical racks — are the basis of the structure that support the entire system.

2. Horizontal crossbars — connect the racks to each other and create a stable working platform.

3. Diagonal ties — provide additional stability and prevent lateral fluctuations.

Wedge-shaped scaffolding, due to its characteristics, is widely used in construction and other industries that require strict safety and efficiency standards.

Features of wedge forests:

1. Versatility: these scaffolds are suitable for various construction tasks, including the construction of new buildings, repair and reconstruction work, as well as for the installation and dismantling of various structures.

2. Ease and precision of assembly: the assembly of wedge scaffolding is easy and fast. The nodes are fixed with a simple hammer blow, which eliminates the need for additional tools and significantly speeds up the installation process.

3. Safety: The wedge scaffolding design allows for evenly distributed load and provides a high level of safety for workers at height.

Tube abd clamp scaffolding

They are an efficient spatial frame-and-tier system consisting of tubular elements such as struts, ties, and crossbars. These elements are interconnected using pivoting and blind clamps, which provides high flexibility in the design and installation of scaffolding.

Features and advantages of yoke scaffolding:

1. Flexible in application: Yoke scaffolds are ideal for working with complex architectural shapes and sloping bases, making them versatile for various construction tasks.

2. Installation height: they can be used for construction and finishing work at a height of up to 100 meters, which allows work to be carried out on the facades of high-rise buildings and structures.

3. Variety of applications: yoke scaffolding is often used for facade work, restoration of monuments and temples. Their ability to create complex spatial structures makes it possible to effectively solve problems in the context of historical architecture.

4. Construction on inclined bases: the construction of yoke scaffolding allows them to be installed on inclined surfaces, which makes them suitable for use in various conditions, including areas with rough terrain.

5. Stability and reliability: The use of clamps in the connection system ensures structural reliability and durability during operation, which is important to ensure the safety of workers at height.

Thus, yoke scaffolding is a reliable and versatile solution for various construction tasks, which makes them indispensable in modern construction projects.

Cup scaffolding

They are a popular design solution in the construction industry due to their unique characteristics and advantages. They consist of steel pipes with a rigid frame structure, which are interconnected using cup fasteners. This connection ensures the simplicity and speed of assembly, which makes them particularly convenient to use.

Advantages of cup forests:

1. Quick installation: Due to the simplicity of the mounting system, the installation of scaffolding is fast, which greatly speeds up the entire construction process.

2. Reliable fasteners: the cup fastening system ensures a high degree of reliability and stability of the structure, which minimizes risks when working at height.

3. Lack of fasteners and unnecessary fittings: This feature eliminates the need for additional elements that may be lost during disassembly or transportation, which simplifies forest management.

4. High load-bearing capacity: Cup scaffolds have a high load-bearing capacity, which allows them to be used to support significant loads, making them safe to operate and effective for completing tasks.

As a result, cup scaffolding is an effective and reliable solution for construction projects of varying complexity, combining high strength and ease of use.

Wedge scaffolding

They are an important element of construction technologies, providing convenient and safe access to work sites. Their main structure consists of tubular elements, which gives them lightness and strength.

Wedge-shaped scaffolding, due to its characteristics, is widely used in construction and other industries that require strict safety and efficiency standards.

Key elements of wedge forests:

Vertical racks

are the basis of the structure that support the entire system.

Horizontal crossbars

connect the racks to each other and create a stable working platform.

Diagonal ties

provide additional stability and prevent lateral fluctuations.

Features of wedge forests:

Versatility

these scaffolds are suitable for various construction tasks, including the construction of new buildings, repair and reconstruction work, as well as for the installation and dismantling of various structures.

Ease and precision of assembly

the assembly of wedge scaffolding is easy and fast. The nodes are fixed with a simple hammer blow, which eliminates the need for additional tools and significantly speeds up the installation process.

Safety

The wedge scaffolding design allows for evenly distributed load and provides a high level of safety for workers at height.

Tube abd clamp scaffolding

They are an efficient spatial frame-and-tier system consisting of tubular elements such as struts, ties, and crossbars. These elements are interconnected using pivoting and blind clamps, which provides high flexibility in the design and installation of scaffolding.

Thus, yoke scaffolding is a reliable and versatile solution for various construction tasks, which makes them indispensable in modern construction projects.

Features and advantages of yoke scaffolding:

Flexible in application

Yoke scaffolds are ideal for working with complex architectural shapes and sloping bases, making them versatile for various construction tasks.

Installation height

they can be used for construction and finishing work at a height of up to 100 meters, which allows work to be carried out on the facades of high-rise buildings and structures.

Variety of applications

yoke scaffolding is often used for facade work, restoration of monuments and temples. Their ability to create complex spatial structures makes it possible to effectively solve problems in the context of historical architecture.

Construction on inclined bases

the construction of yoke scaffolding allows them to be installed on inclined surfaces, which makes them suitable for use in various conditions, including areas with rough terrain.

Stability and reliability

The use of clamps in the connection system ensures structural reliability and durability during operation, which is important to ensure the safety of workers at height.

Cup scaffolding

They are a popular design solution in the construction industry due to their unique characteristics and advantages. They consist of steel pipes with a rigid frame structure, which are interconnected using cup fasteners. This connection ensures the simplicity and speed of assembly, which makes them particularly convenient to use.

As a result, cup scaffolding is an effective and reliable solution for construction projects of varying complexity, combining high strength and ease of use.

Advantages of cup forests:

Quick installation

Due to the simplicity of the mounting system, the installation of scaffolding is fast, which greatly speeds up the entire construction process.

Reliable fasteners

the cup fastening system ensures a high degree of reliability and stability of the structure, which minimizes risks when working at height.

Lack of fasteners and unnecessary fittings

This feature eliminates the need for additional elements that may be lost during disassembly or transportation, which simplifies forest management.

High load-bearing capacity

Cup scaffolds have a high load-bearing capacity, which allows them to be used to support significant loads, making them safe to operate and effective for completing tasks.

Areas of application of scaffolding

- residential and public buildings

- bridges and tunnels

- repair, reconstruction, restoration

- space and aviation industry

- shipbuilding and ship repair

- stages, grandstands, sets and movie studios

- Power industry (TPPs, HPPs, NPPs)

- oil refineries

- cement plants

- chemistry and petrochemistry

- pulp and paper mills

- metallurgy

- gas industry

- exploration and production

- food industry

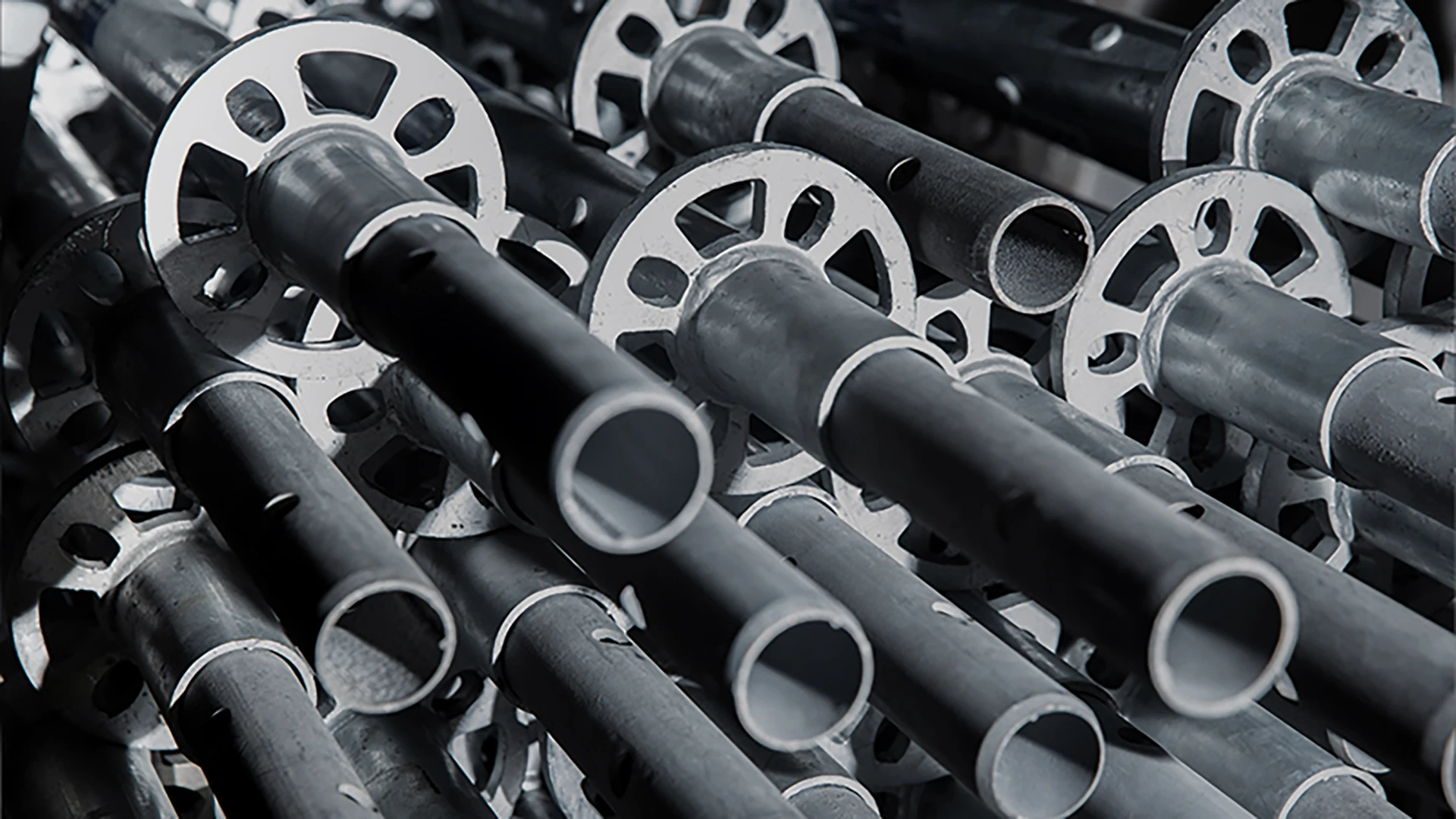

Own production in Izhevsk

of shares of SOYUZ companies have been owned by POLATI since 2024

The SOYUZ scaffolding plant is the first manufacturer in Russia to produce world-class modular wedge-type scaffolding. It provides services for the sale and rental of scaffolding worldwide, as well as training personnel in the professional use of scaffolding. Special steel is used in the production of pipes and casting blocks.

of shares of SOYUZ companies have been owned by POLATI since 2024

The total production area of SOYUZ is 13,000 m2 and includes high-precision casting production, automatic welding stations, roll forming lines, molding production, and laser cutting sections.

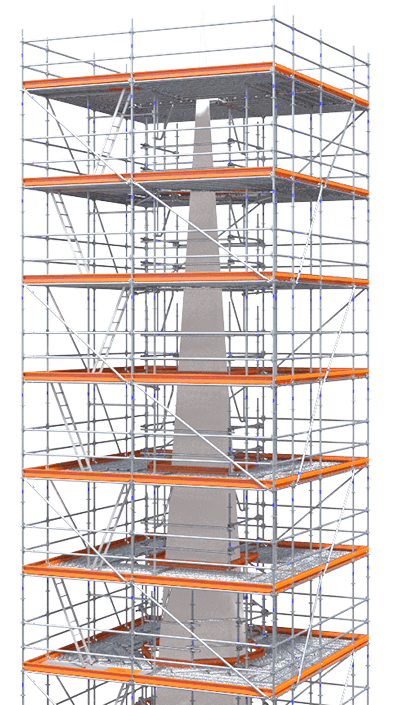

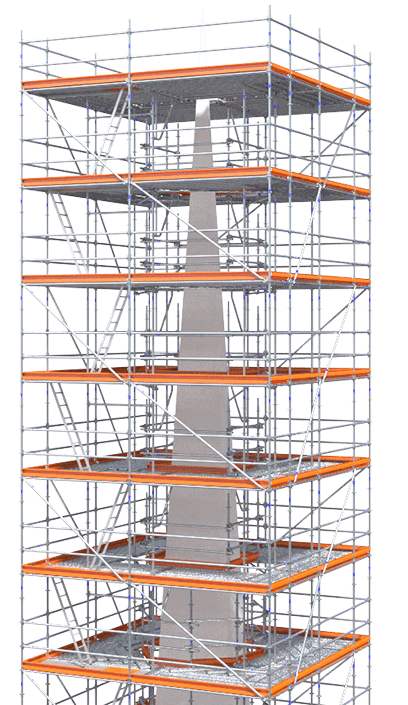

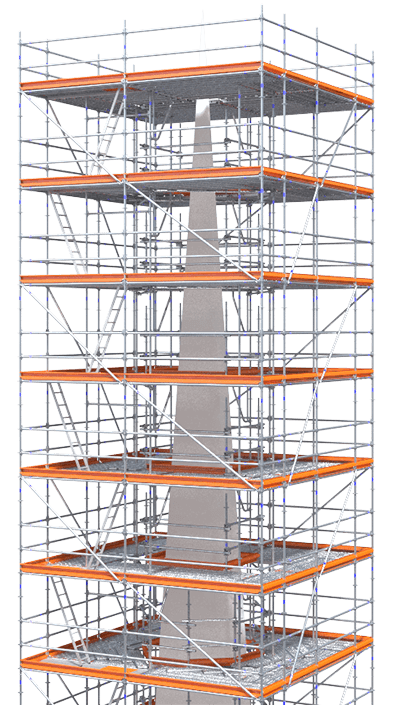

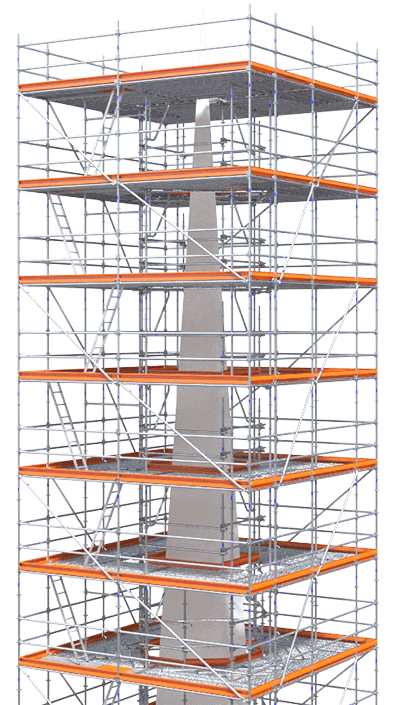

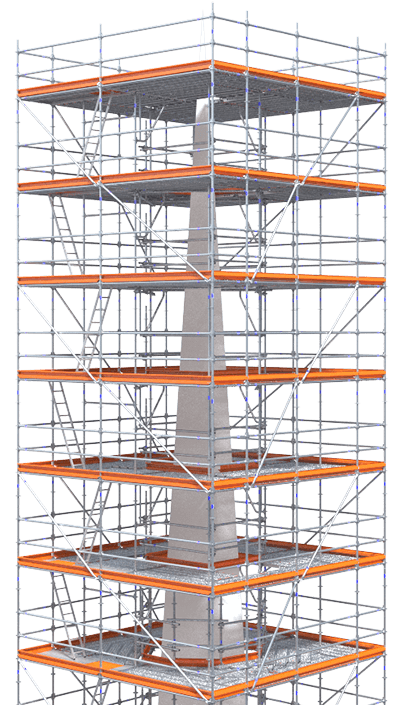

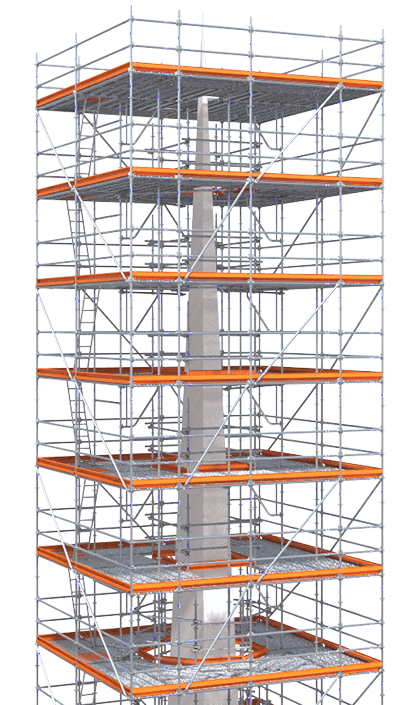

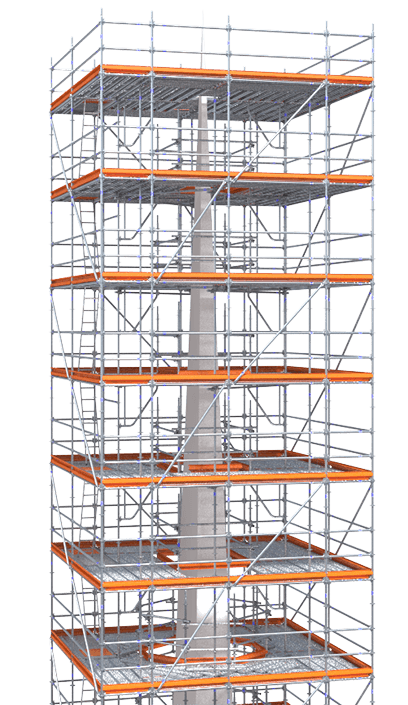

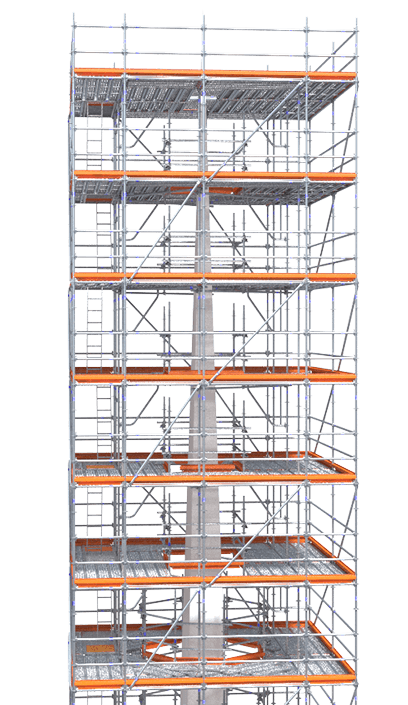

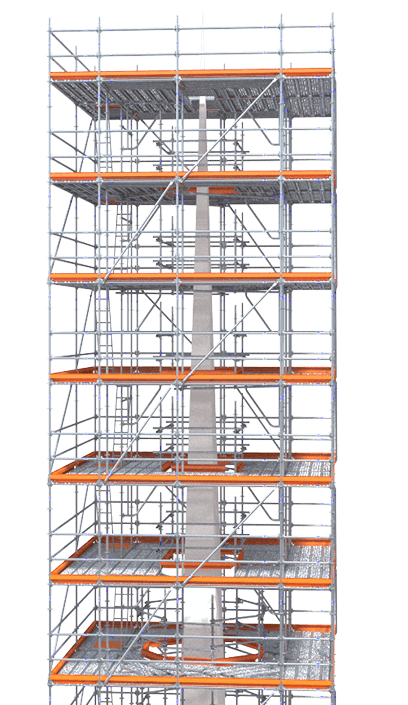

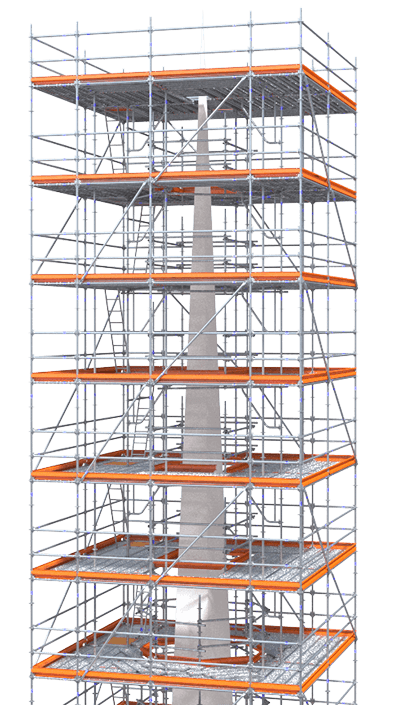

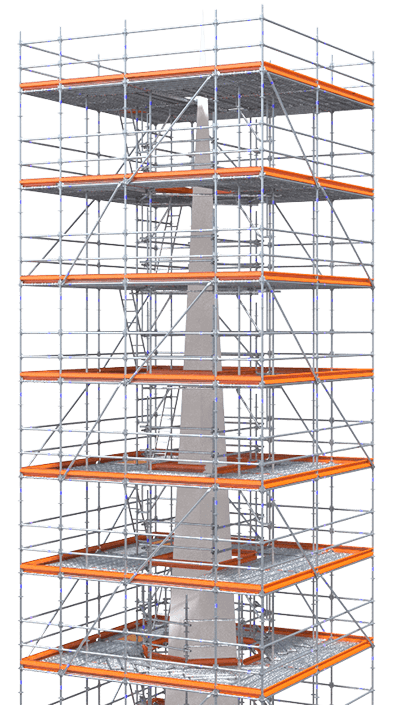

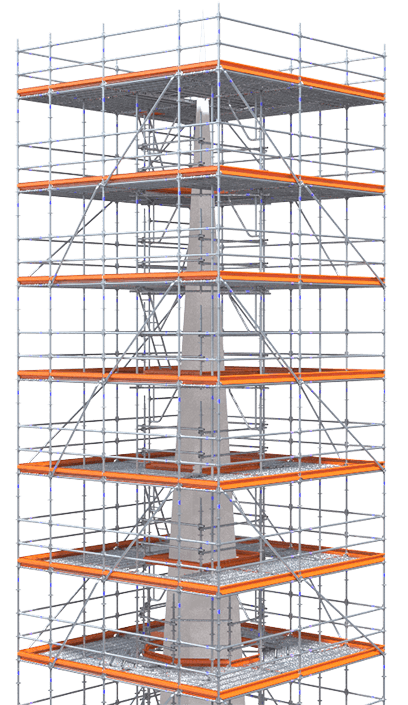

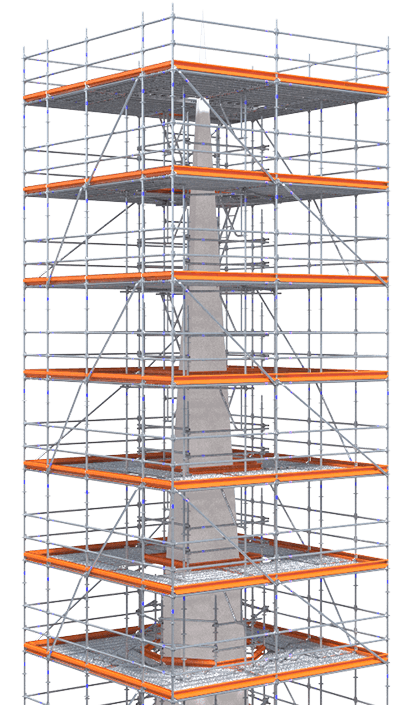

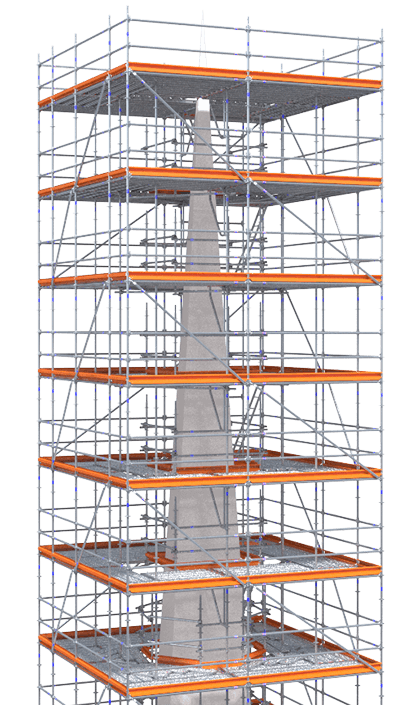

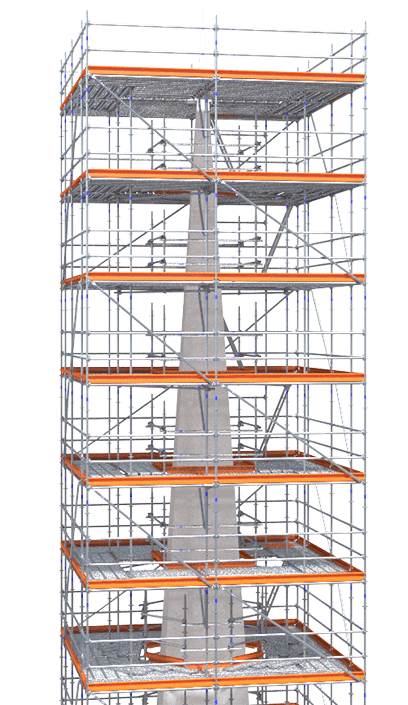

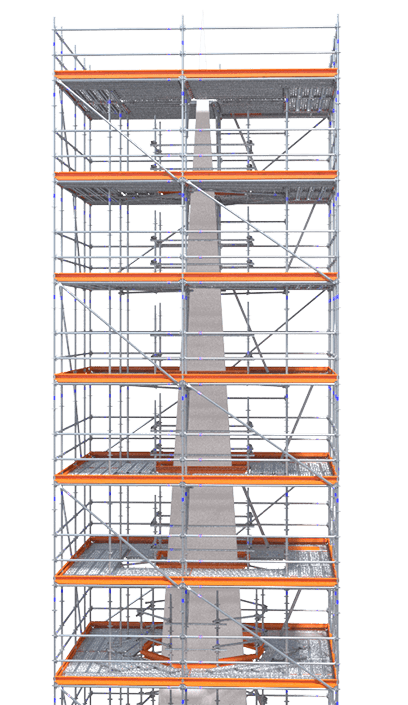

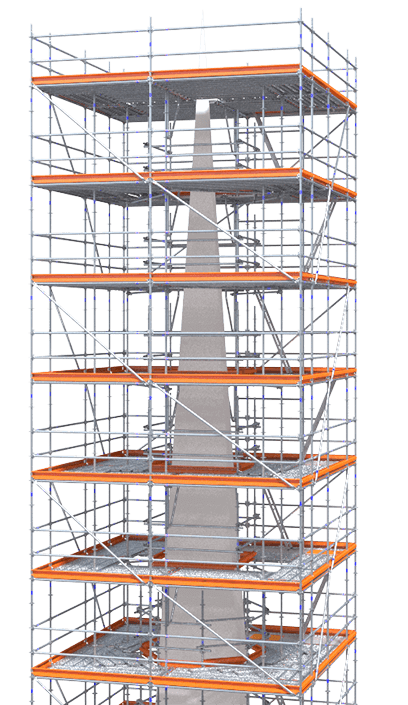

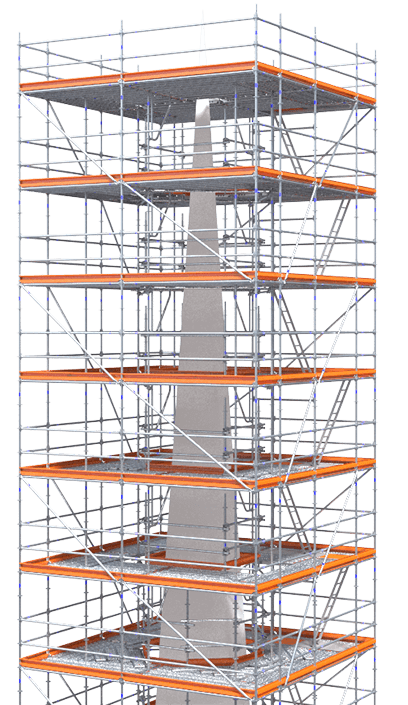

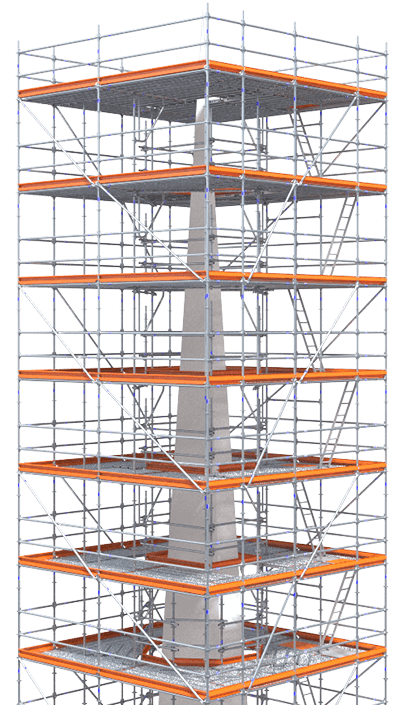

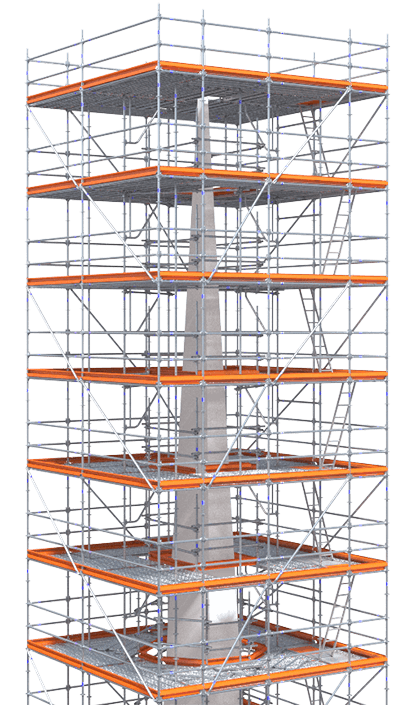

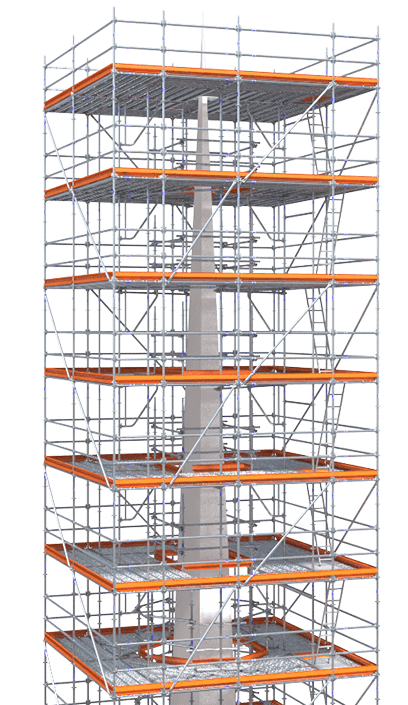

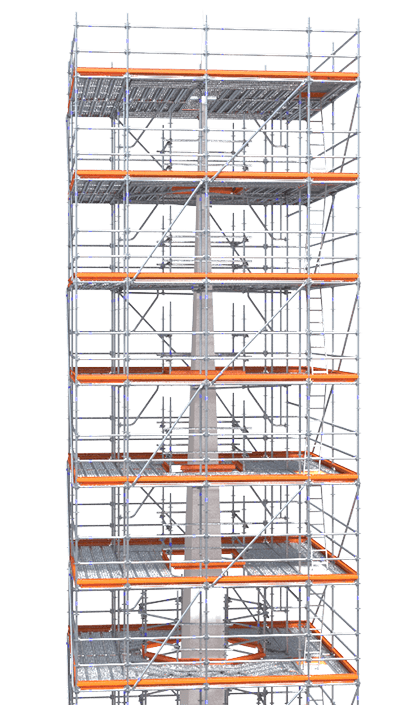

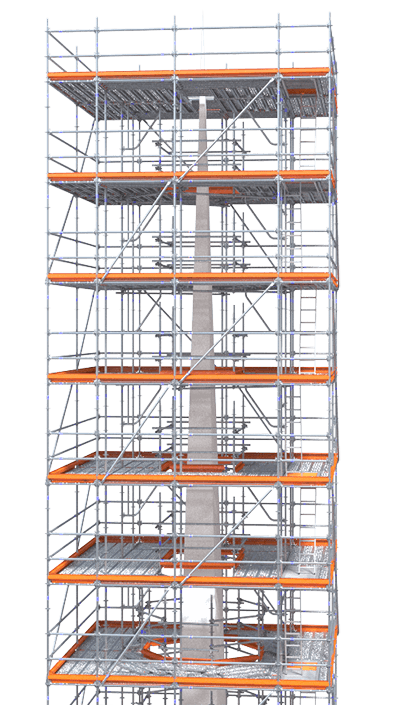

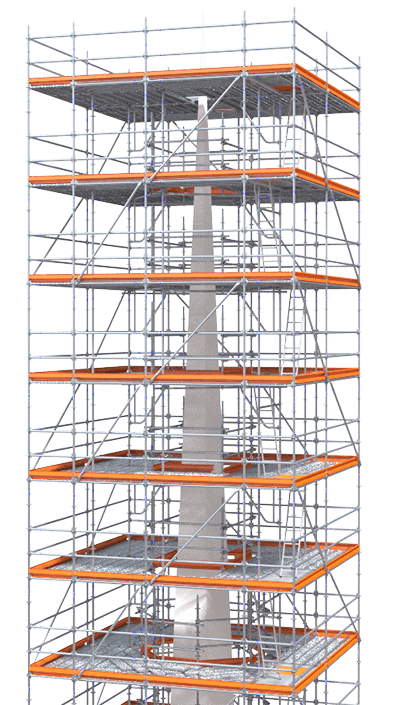

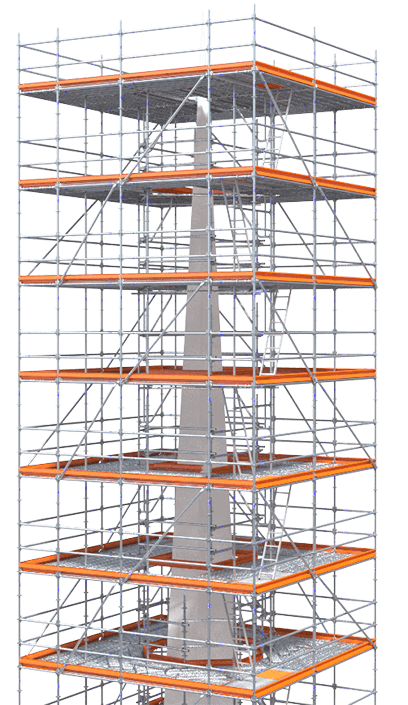

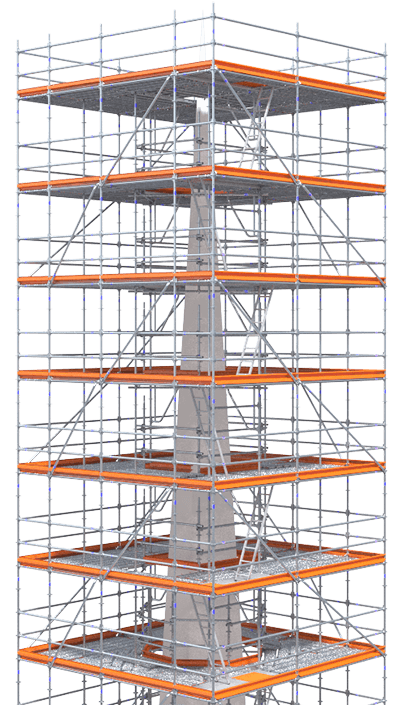

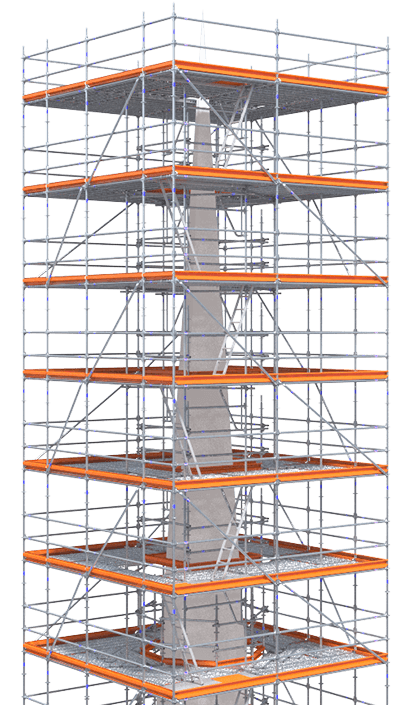

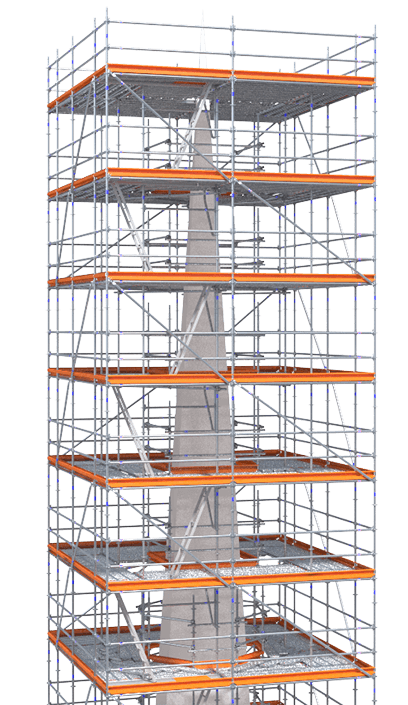

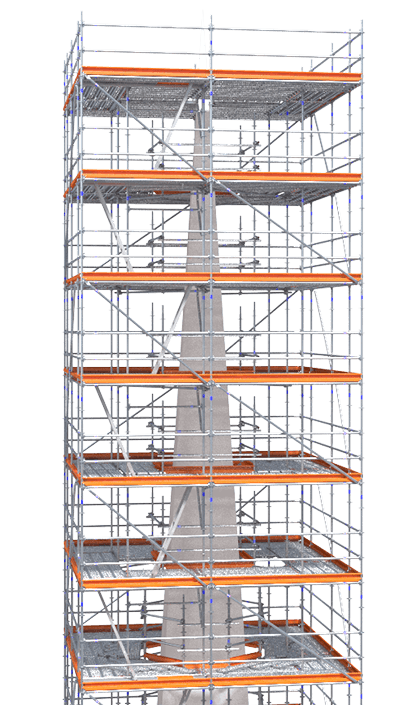

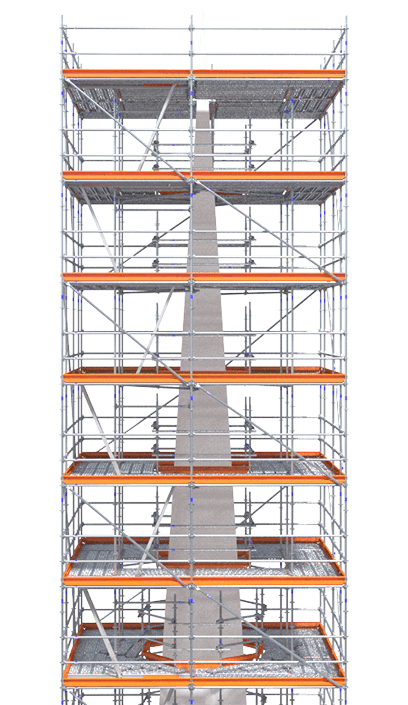

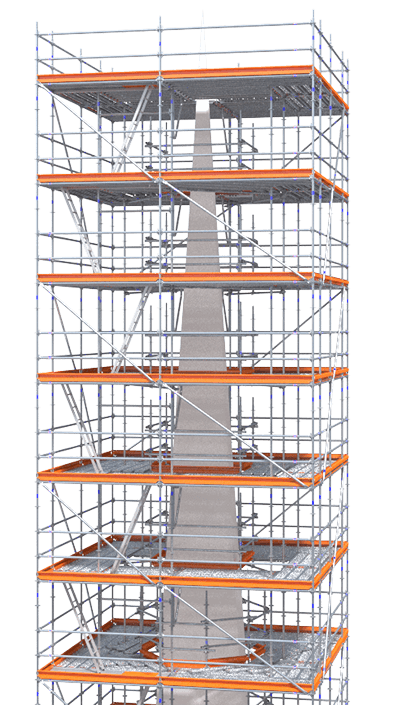

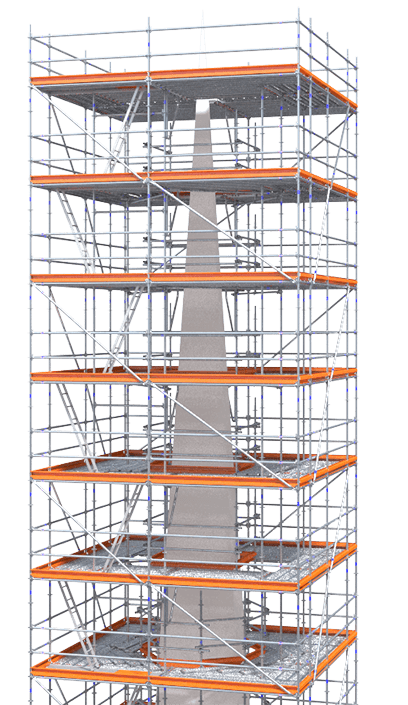

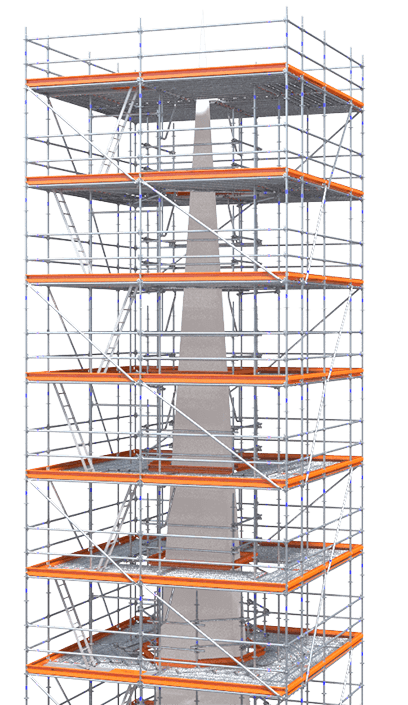

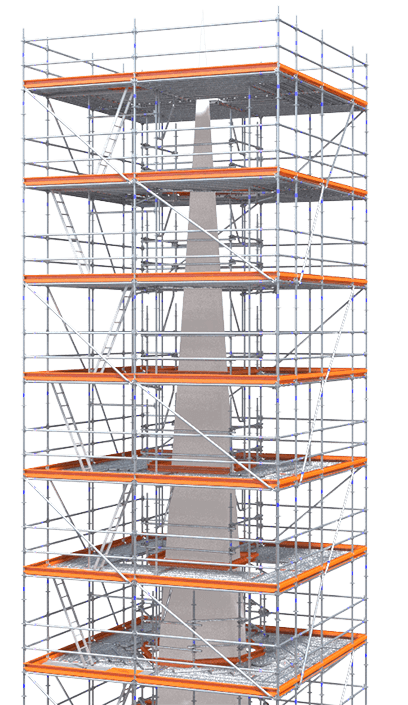

3D scaffolding project

3D modeling is the development of a spatial virtual model based on source data in order to increase the visibility, accuracy and applicability of the technical solution being developed The 3D model allows you to look at the construction of scaffolding from all sides and assess compliance with the tasks set.

When developing a constructive solution, the work includes the following steps

- receiving a request for the development of a scaffolding structure

- identification of all customer's needs

- source data collection

- development of a 3D model of the scaffolding structure and visualization in a form convenient for the customer

- coordination of the developed technical solution, making adjustments

- specification output

- transfer of the agreed technical solution to other services of the company for further work

Security and expertise

The POLATI company allocates a budget for investing activities aimed at safe working conditions. Employees are provided with food, accommodation, high-quality tools and equipment for work. We have developed special clothes and provided them to our employees. We invest in the education and professional training of our employees and ensure that the qualifications of each of them correspond to their profession, and the Department of Labor Protection, Industrial Safety and Environmental Protection annually organizes the training of its occupational safety specialists.

Opportunities

Warehouses

All warehouses of the POLATI company are maximally improved and equipped with the necessary equipment

warehouse area in Russia and abroad

spent objects

Technic

The POLATI company has a large number of equipment available that performs a number of necessary functions at the facility: transportation of materials, loading and unloading, transfer for employees, construction and installation work. All equipment is purchased only from the best manufacturers and is approved by customers. Our fleet of vehicles consists of 55 units.

material handling machines

loading equipment

a car for the needs of employees

/Хайдельберг_2.webp)

.webp)

.webp)

.webp)