Tasnee Tower

One of the first Saudi companies to invest in the petrochemical market since the mid-90s. The company is currently one of the largest petrochemical producers in Saudi Arabia.

Отработано человеко-часов

2 082Объём лесов, м³

1 300отработано человеко-часов

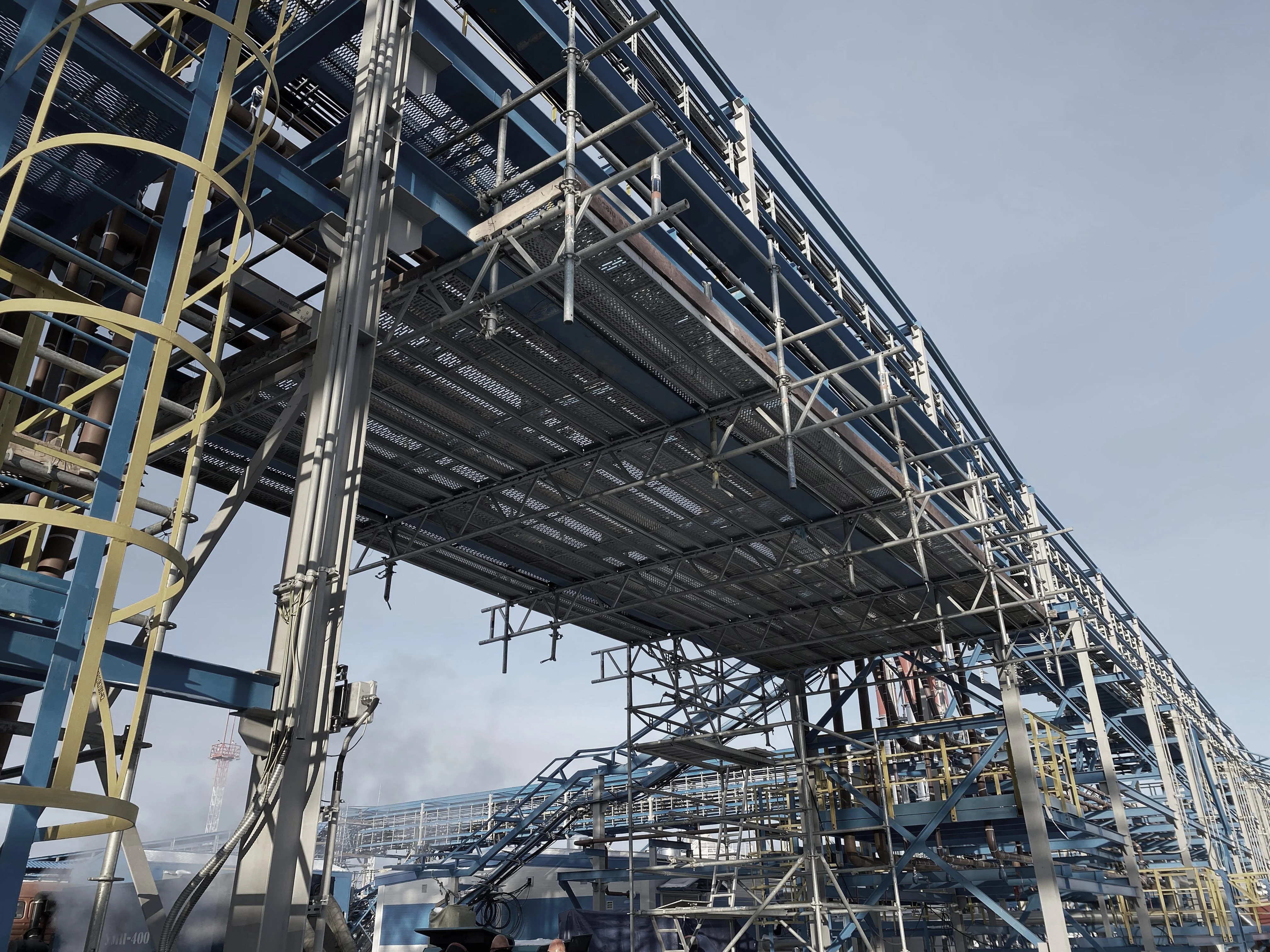

POLATI erected and dismantled scaffolding in the AA section of the Tasnee plant. The scaffolding erection was necessary for inspection and defect removal on a 1.5 m diameter and 60 m high separator. The design and erection of the structure was complicated by the large amount of interference from: support masts, fixed platforms, ladders and auxiliary piping. Prior to scaffolding inspection of the equipment, the customer was unable to determine the need for partial dismantling of the separator sections, so the scaffolding design had to provide access to all necessary parts of the installation with the possibility of partial dismantling of the separator without modification of the scaffolding.

Prior to inspecting the equipment from the scaffolding, the customer was unable to determine the need to partially dismantle the separator sections, so the scaffolding had to be designed to provide access to all necessary parts of the installation with the ability to partially dismantle the separator without modifying the scaffolding.

Based on the results of the inspection, the customer identified the need to replace bolts on all flange connections, as well as sandblast and paint the entire lower section.

The deadlines for the work were strict, which made many contractors refuse to undertake it, but for POLATI it was not a problem. The work was completed on time, due to the high quality and high speed of installation of PERI Saudi Arabia material. Delivery and installation were completed in 9 days, dismantling in 5 days with full demobilization of the material.

TASNEE was satisfied with the work done and the timing of the work.